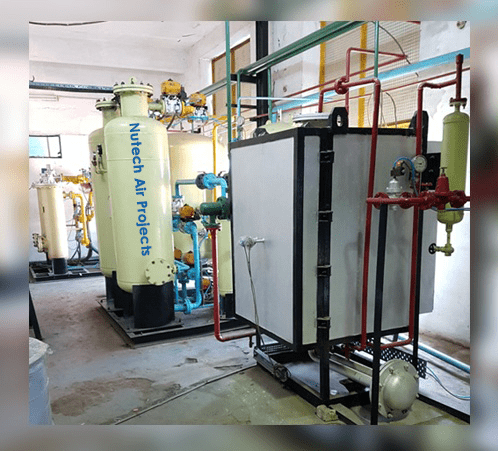

Nutech Air Projects is leading the industry of PSA Nitrogen Gas Plant Manufacturers. We are working in the well-versed environment of technology and science. We are working with a team of highly proficient engineers who are working with an expert end to come up with the well-engineered PSA Nitrogen Gas Generator Manufacturers.

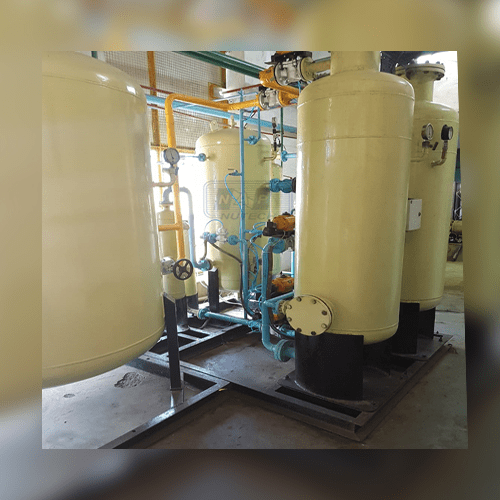

These PSA Nitrogen Gas Plants is made for the separation process with a proven technology which leads to an effective and efficient system of the program. These Nitrogen Gas Plants are made in the compact size that requires less space.

Product Details:

| Minimum Order Quantity | Customer Requirement |

| Usage/Application | Industrial |

| Automatic Grade | Automatic |

| Design | Customized |

| Capacity | 5 Nm3/Hr onwards |

| Brand | Nutech Air Project |

| Material | Mild steel |

| Colour | White |

| Product Purity | 99.5% onwards |

| Condition | New Only |

| Air Pressure MPA | 0.7~0.8 |

| Power | 5.5 kW |

| Voltage | 380 V |

Salient Features of Nitrogen Gas Plant Generators

- Modular Design

- Safe & Reliable

- Hassel-free, easy to use & install

- Completely Pre-manufactured Skids

- Fast Start-up. Fully automatic and unattended operation

- Low-cost on-site production

- Provide stable long term N2 Cost

Standard System Design

- Automatic Pressure Control, Flow control, Purity control

- Alarms systems for visual, audible or output contacts

Advantages Of Nitrogen Gas Generator

- Independence from external gas suppliers and from the fluctuation of the market price.

- Suppression of logistics operations with cylinders or liquid Nitrogen and supplier management.

- Modular, flexible and low maintenance units as compared to Cryogenic Liquid Nitrogen plants.

- Don’t waste more money with Nitrogen Cylinders /Cryogenic Liquid N2 tanks.

Our Products is an efficient & Energy-Saving.

Applications of PSA Nitrogen Gas Generators

- Inertization Process (Chemicals, Petrochemical)

- Oil & Gas (Blanketing, Filling, Transferring)

- Food Packet( Pouch Packaging, Confectionaries)

- Tyre Filling (Automobiles)

- Power Sector

- Electronics Industries

- Autoclaves Segments

- Cement Industry

- Metallurgical Industry

- Synthetic & Fiber Industry

- Chemical Industries & Laboratories (LCMS, GC)

- Food Packaging Industry

- Pharmaceutical Industry

- Optical Fiber Industry

- Electronic Industry

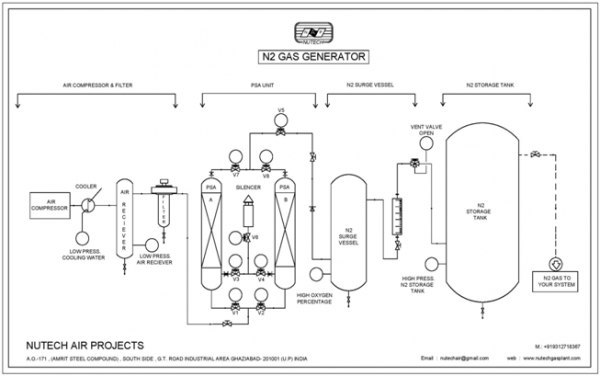

PSA process consists of 2 vessels filled with Carbon Molecular Sieves (CMS) and Activated Alumina. Clean compressed air is passed through one vessel and nitrogen comes out as product gas. The exhaust gas (Oxygen) is discharged back into the atmosphere. Upon saturation of the molecular sieve bed, the process switches nitrogen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Thus 2-vessels keep cycling alternately in Nitrogen production and regeneration ensuring Nitrogen gas is continuously available to your process.

Atmospheric air comprises of 78% Nitrogen and the PSA process utilizes CMS to extract this Nitrogen from the air.

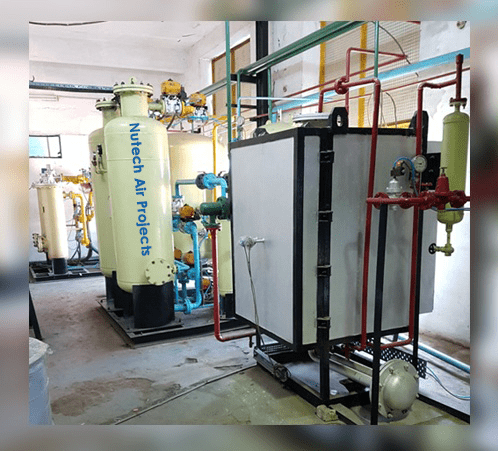

Nutech Air Projects is a leader of PSA Nitrogen Gas Plant Manufacturers. We are working in the well-versed environment of technology and science. Nutech Gas Plant aimed at manufacturing the plants for various types of gases and usages.

We are working with a team of highly proficient engineers who are working with an expert end to come up with the well-engineered PSA Nitrogen Gas Generator Manufacturers which are made with the cost-effective advanced technology.

These PSA Nitrogen Gas Plants has made for the separation process with a proven technology which leads to an effective and efficient system of the program. These consist of 2 vessels with molecular sieves and alumina which are compressed at 30 degrees C temperature. This extracts out the oxygen and exhausted gas Nitrogen is discharged into the temperature. These Nitrogen Gas Plants are made in the compact size so that it requires less space. These are made reliable to get used and are well tested with technological equipment. It was made to do less power consumption and least maintenance requirement. We are offering them within a reasonable range and in the supreme quality.

TECHNICAL FACTS

FLOW RANGE

Suitable for flows from 1 to 1500 nm3/hr. higher flows can achieve using multiple PSA units.

NITROGEN PURITY

Purity from 98% to 99.999% is possible directly with a simple PSA unit. We recommend using our DX or Copper-DX models for higher guaranteed purity levels up to 99.9999%.

PRESSURE

Most customers will find a system offering nitrogen at 5 kg/cm2g pressure quite suitable. However, we can deliver nitrogen directly up to 10 kg/cm2g pressure without a booster compressor.

DEW POINT

Our generators deliver very dry nitrogen gas, with dew point as low as (-) 80°C. We also offer measuring instruments for online detection of gas dryness

MS-N MODEL PSA Nitrogen Gas Plant

DX-N, MODEL PSA Nitrogen Gas Plant

CU-DX-N, MODEL PSA Nitrogen Gas Plant